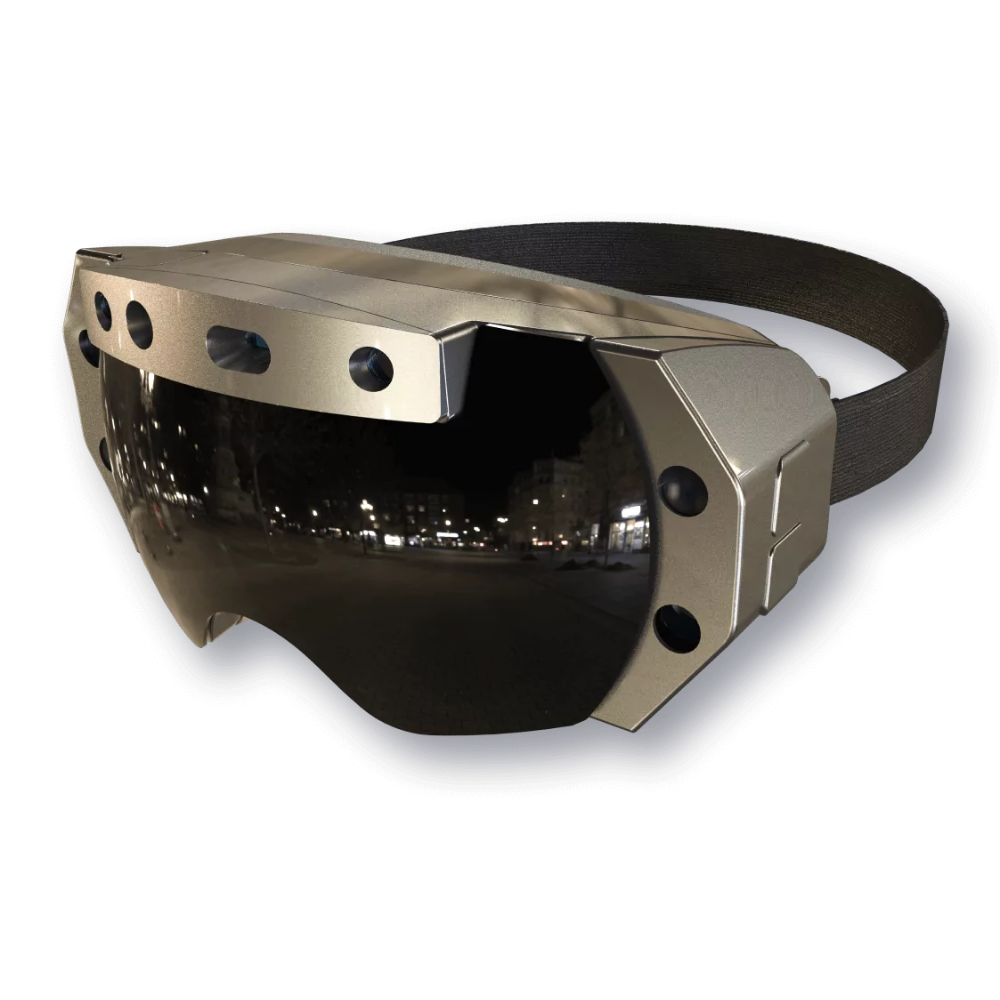

EVT, DVT, and PVT are often seen as lengthy hurdles, yet they form the backbone of reliable hardware product development. Each phase systematically reduces risk, validates performance, and ensures manufacturability—transforming early concepts into market-ready products. At Axio Electronics, we follow a rigorous validation path to guarantee that every device not only works but thrives in real-world conditions.

Engineering Validation Test (EVT) - Functional Prototype Bring-up- Power, Clock, Reset Verification - Sensor & Peripheral Testing - Core Feature Validation

Design Validation Test (DVT) - Full Spec Compliance Testing - Environmental & Reliability Stress Tests - Certification & Pre-Compliance (FCC/CE/EMC) - Firmware & Hardware Integration Validation

Production Validation Test (PVT) - Pilot Production Run (100–500 units) - Assembly Line Test Jig Implementation - Yield Analysis & Process Optimization - Mass Production Readiness & QA

EVT ,DVT ,PVT is a comprehensive suite of tools designed to streamline the development and testing process for hardware products. It offers a range of features that help developers catch defects early, ensure quality, and deliver reliable products to customers.

- Risk Reduction: Catch defects before they scale.

- Quality Assurance: Meet performance targets in all conditions.

- Scalability: Ensure manufacturing is cost-effective and repeatable.

- Customer Confidence: Deliver safe, reliable, and certified hardware.

OUR CASE STUDY

EVT + DVT + PVT Testing Guide & Timeline

EVT (Prototype Bring-up & Functional Validation)

2 weeksEVT (Core Feature Testing)

DependsDVT (Design Validation & Reliability)

2 WeeksDVT (Certification & Compliance Prep)

2 WeeksPVT (Pilot Production Run)

4-6 WeeksPVT (Mass Production Readiness)

2 WeeksOngoing QA, Yield & Feedback Loop

OngoingExpert Rapid Prototyping for Faster Product Development

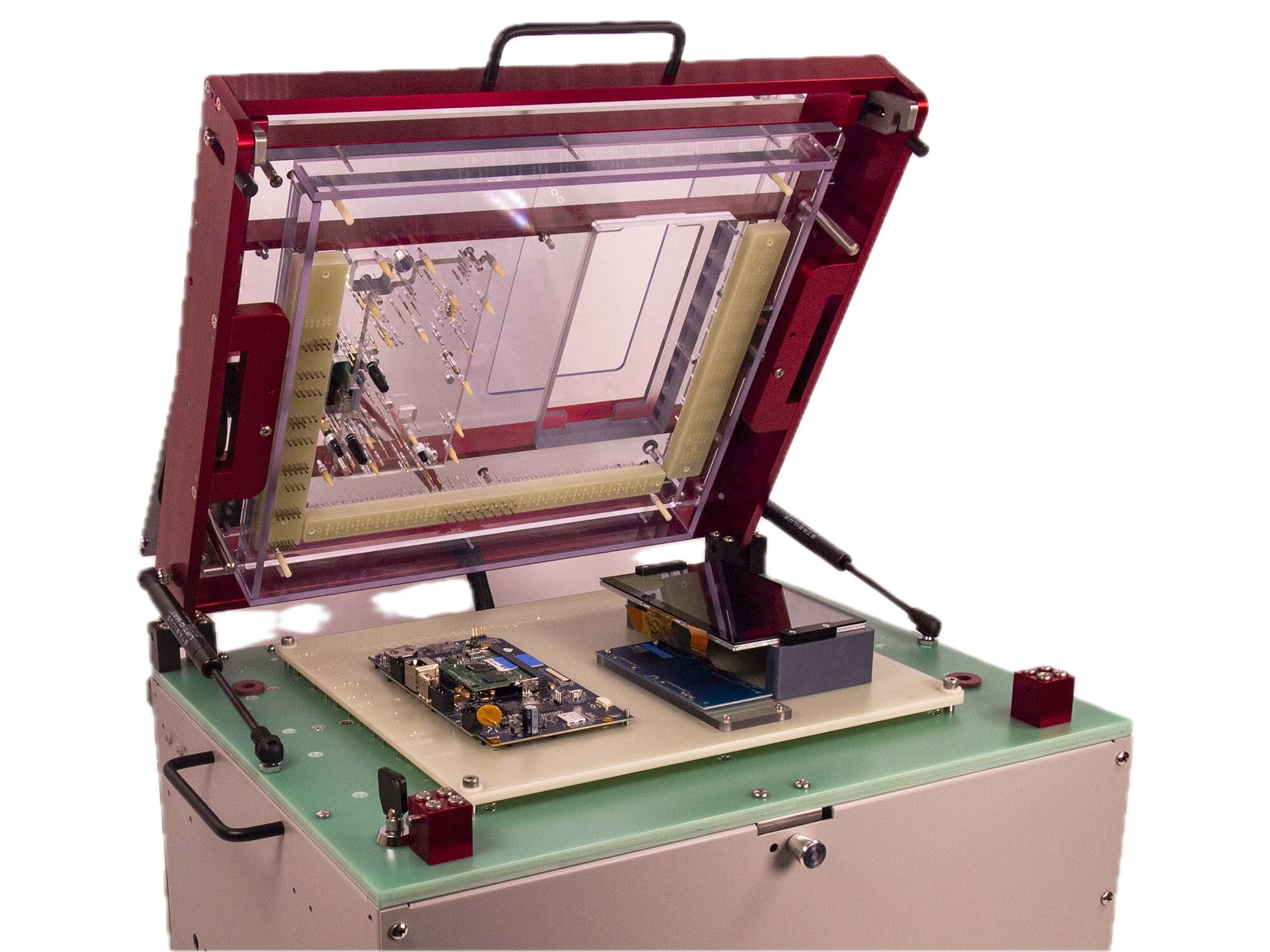

At Axio Electronics, we rapidly prototype ideas into test-ready products using in-house PCB fabrication, 3D printing, and firmware integration for faster validation.

We optimize designs with hardware, firmware, and mechanical teams, ensuring performance and scalability. With 50+ projects, we deliver cost-effective, market-ready solutions.

ENGINEERING VALIDATION TESTING

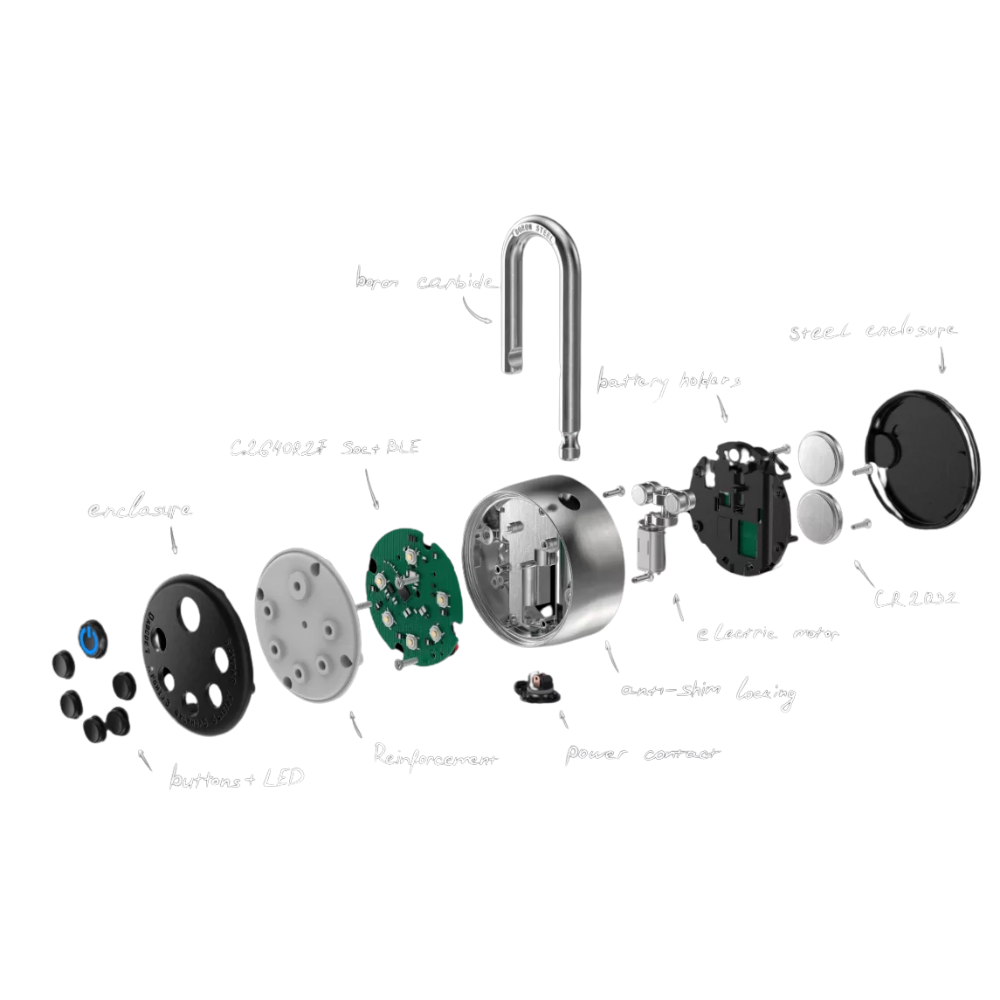

PCB Testing & Debugging – Oscilloscope, Multimeter, Logic Analyzer

Power Consumption Analysis – Otii Arc, Monsoon Power Monitor

Wireless Connectivity Testing – RF Spectrum Analyzer, Network Protocol Analyzer (Wireshark, nRF Connect)

Sensor Accuracy Testing – DAQ Systems, Environmental Chambers

Firmware Debugging – JTAG Debugger, Embedded IDEs (STM32CubeIDE, Keil, MPLAB)

DESIGN VALIDATION TESTING

PRODUCTION VALIDATION TESTING

Pilot Production Batch Testing – Automated Test Equipment (ATE), Functional Test Fixtures.

Factory Yield & Assembly Consistency – Inline Optical Inspection (AOI), X-ray Inspection.

Final QA/QC Defect Detection – Automated Optical Inspection (AOI), Functional Testing Stations.

Regulatory Compliance Certification – FCC, CE, UL, ISO, FDA testing via certified laboratories.

Packaging & Logistics Verification – Drop Test Machines, Environmental Chambers.

How we communicate?

Bi-weekly technical calls, Weekly PDF reports, Robust version control, project management access

Deliverables

(Timeline - 8-12 Weeks)*

- Fully Tested & Debugged Functional Prototype – Ensuring hardware meets design and performance requirements.

- Power & Connectivity Performance Report – Detailed insights on power consumption, wireless performance, and sensor accuracy.

- Mechanical & Environmental Durability Report – Results from waterproofing, impact, thermal, and vibration testing.

- Regulatory Compliance & Certification Support – Assistance in meeting FCC, CE, UL, ISO, FDA, and other standards.

- Manufacturing & Assembly Readiness Report – Evaluating production efficiency, quality control, and defect analysis.

- Pilot Production Batch Results – Verification of factory yield, assembly consistency, and scalability assessment.

DOWNLOAD SAMPLE

EVT, DVT, PVT

DOCUMENTS

We prepare for next steps

Prepare development plan from idea to manufacturing

Get a financial proposal for development

FAQ’s

What is the purpose of EVT, DVT, and PVT testing?

How accurate are the testing results?

What equipment do you use for EVT, DVT, and PVT testing?

How long does each testing phase take?

Do you provide compliance testing support?

Can we skip EVT and move directly to DVT or PVT?

What deliverables will we receive after EVT, DVT, and PVT?

LET'S TALK ABOUT YOUR PROJECT.

PLEASE FILL OUT THE FORM AND WE'LL GET BACK TO YOU SHORTLY.

Axio Electronics

Axio Electronics